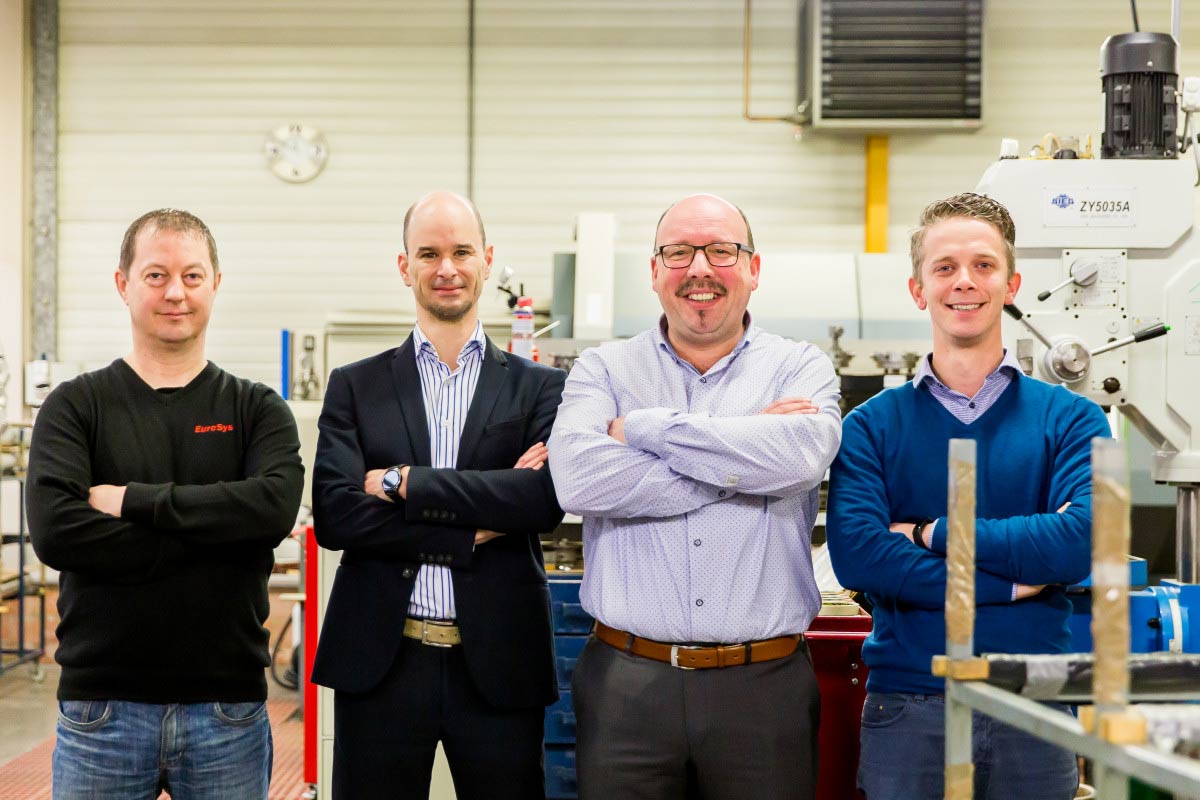

Manufacturing company Teksam Company wants to digitise and automate its internal processes and needed a more powerful and reliable IT infrastructure to do so. EuroSys renewed the servers and installed Wi-Fi in the warehouses and production environment. In combination with a new ERP system and touchscreen PCs in production, TeksamCo can now monitor the entire production planning much better, making everything faster and more efficient.

"Our server infrastructure was gradually becoming obsolete and therefore did not offer enough computing power for our new requirements," says Serge Do Ceu, financial director at TeksamCo. "Moreover, the guarantees were going to expire, with all the risks in terms of security and support. So we started looking for a new solution."

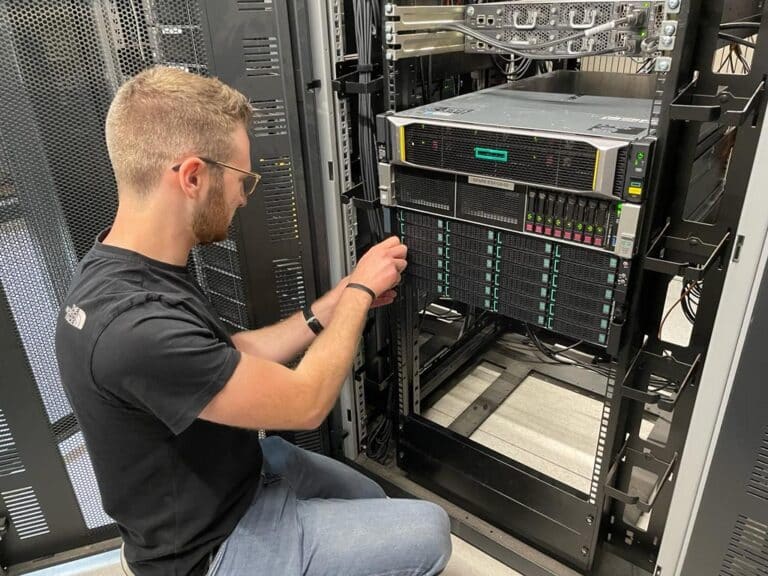

Powerful and redundant infrastructure

"Everything is deduplicated and there is a permanent backup to another building, so the risk of downtime is very low," confirms Serge Do Ceu. "The backup is also much faster now and more reliable than before. Back then we worked with backup to external disks whereas now we have a backup server: a big improvement. Eleven virtual servers run on our Dell PowerEdge VRTX server, so there are no conflicts between the different databases."

Work faster and more efficiently

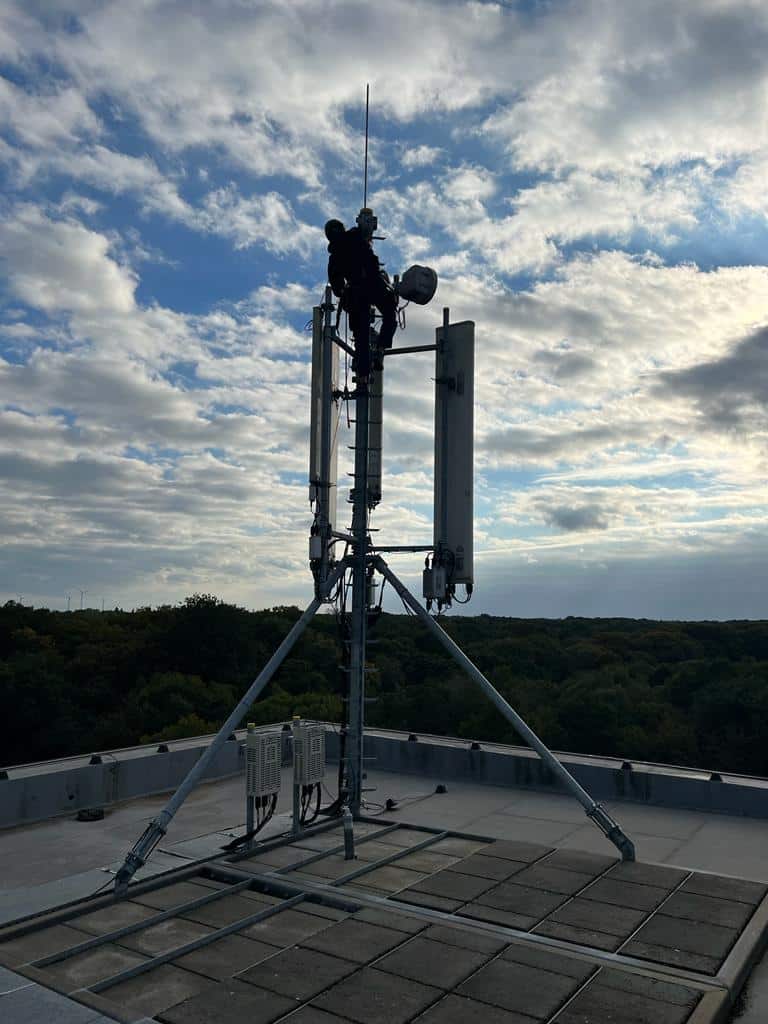

Besides the new server infrastructure - including fibre cables and 10Gbit switches - EuroSys also installed Wi-Fi in the warehouses and production halls. PCs with ergonomic touchscreens were also installed in the production area. "We are fully engaged in the digitisation and automation of all our production processes," explains Serge Do Ceu.

"In that context, we switched to a new ERP system, which was an additional reason to invest in a reliable and high-performance server infrastructure. Our old servers did not offer enough computing power to support the new ERP software. Thanks to the new ERP system in combination with the PCs in the production halls, we can work faster and more efficiently. Indeed, our various internal services and processes, such as sales, logistics, production, administration and accounting, will be much better coordinated. This will allow us to manage stock more efficiently and monitor production in real time. Very important, because we often work with tight deadlines, so a shortage in stock should definitely not be a bottleneck."

Always a real-time view of production planning

That too is now a thing of the past: in our new ERP package, we always have a real-time overview. Moreover, sales staff can also immediately check in the roduction planning which deadline they can set for a new order, as they can see in which timeframe there is room for it. Clearly, this results in an increase in production capacity and better and faster customer service."

The importance of an external IT partner

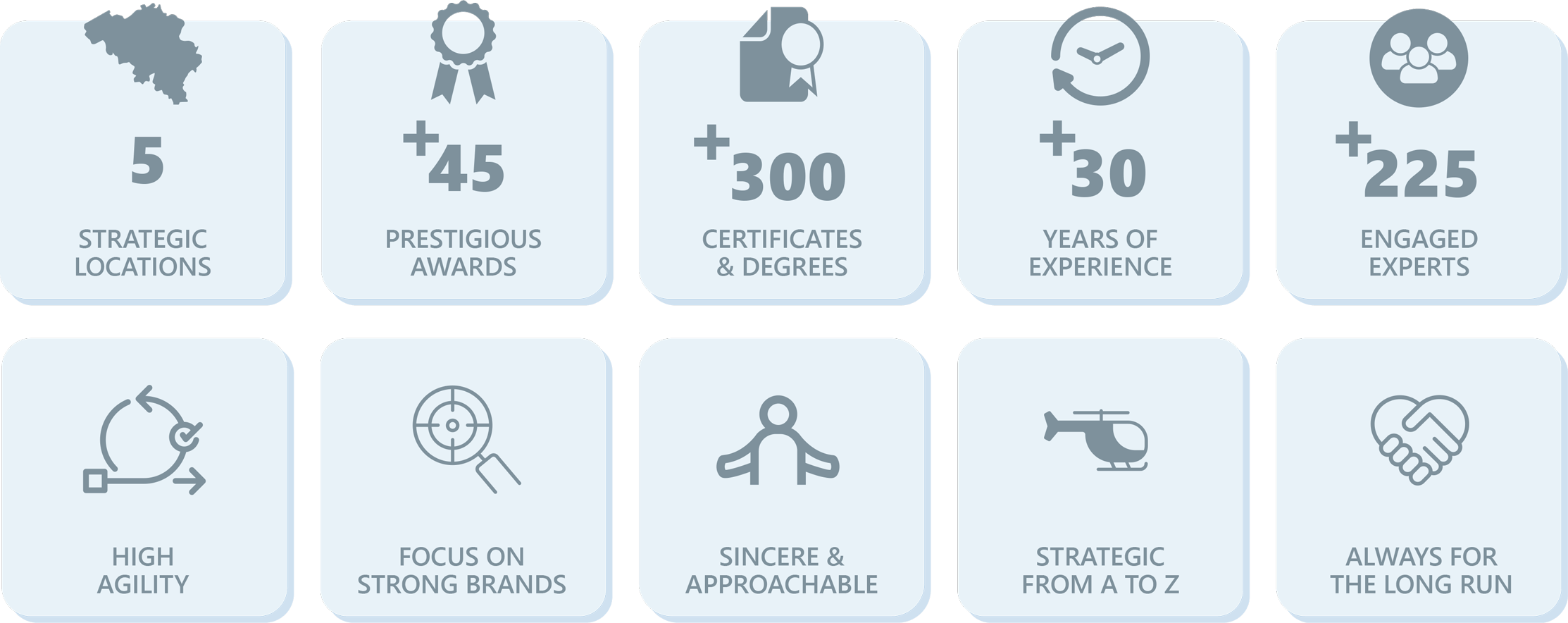

EuroSys, which has been TeksamCo's regular IT partner for ten years, supervised the entire IT infrastructureproject. "We don't have an internal IT department," says Serge Do Ceu. "Indeed, as an SME, that is very expensive and you cannot possibly have all the expertise in-house. It is better for us to outsource everything to a reliable partner like EuroSys. They monitor everything for us. Once again, this project went very smoothly. They proceeded in several steps, from installing the hardware, installing the software and migrating the data to installing the Wi-Fi access points. At no point was there an interruption."

Infrastructure with room for growth

The new set-up is calculated for further growth and TeksamCo therefore expects to be able to continue using the brand-new IT infrastructure for many years to come. "We can get a lot out of it," explains Serge Do Ceu. "For example, we can now also easily perform cost price calculations to keep an eye on our margins. Customers often try to negotiate prices and since 98% of our turnover comes from exports, we have to take into account very fierce global competition. However, we cannot get so far into that price war that our profit margins are compromised, which is why these cost price calculations are very useful. We are also going to work with barcode scanners for monitoring production and logistics. That too requires additional computing power for which we now have the appropriate infrastructure."

Teksam Company manufactures telescopic, fast-extending aluminium mobile masts for lighting, telecommunications and camera surveillance. The company's brand names are Clark Masts, TekMast and Teklite. TeksamCo employs about 50 people, 35 of whom work in production.

- ± 50 employees

- Visit the site of TeksamCo

share this post: